Metal split set making machine

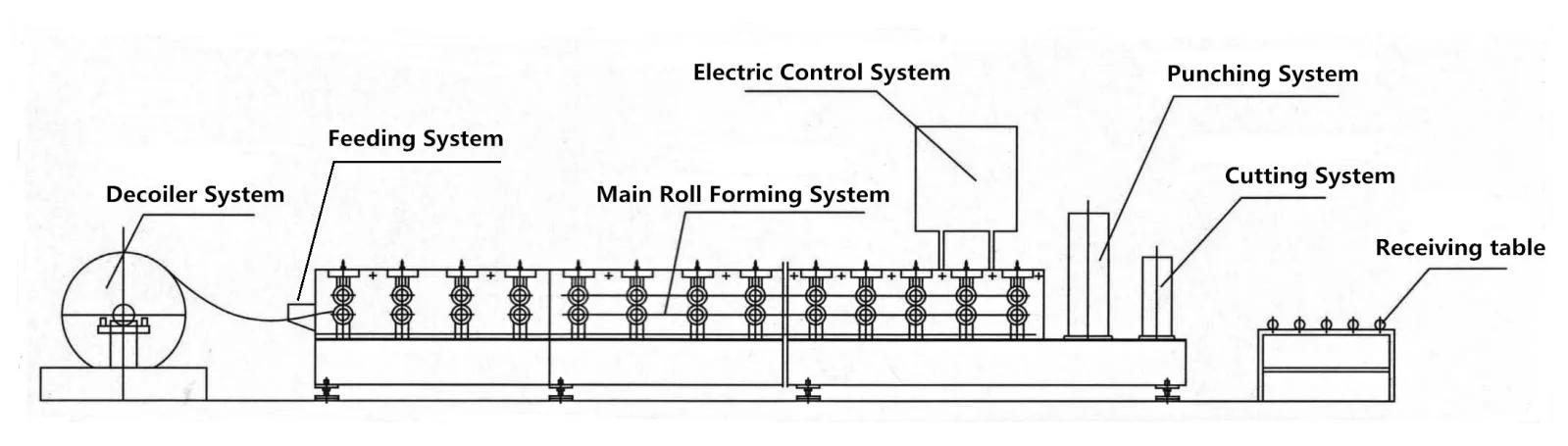

Brief introduction: our metal split set making machine adopt middle plate welded base and memorial arch structure, the base and the structure is heavy duty and high precision, they can guarantee the stable and lifetime of the machine. Our machine adopt the gear box transmission, motor reducer drive. When cut the product to length, the cutter will punch the notch on the end at the same time.

Here below is the split set ready made product photos for you check:

There are several machines contains in the split set system, we can make and supply all those machines for you:

1. Split set making machine

2. Split set plate pressing machine

3. Split set necking machine

4. Split set ring making machine

5. Split set ring welding machine

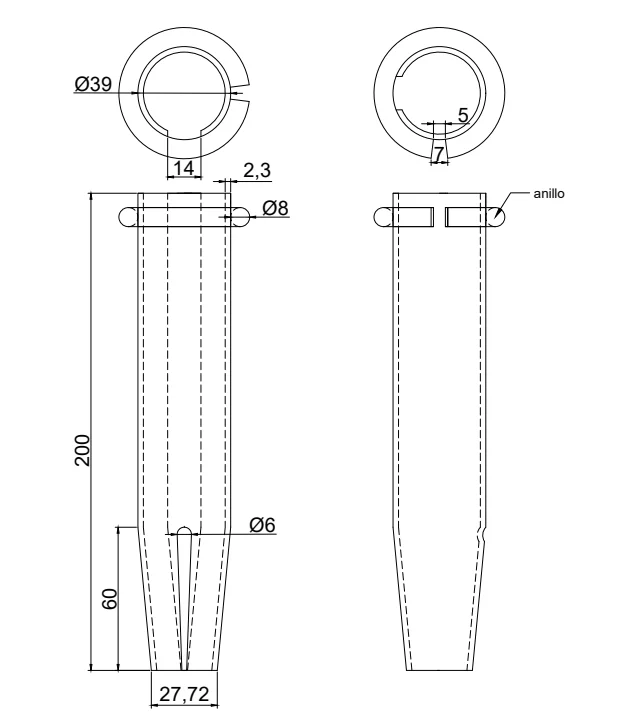

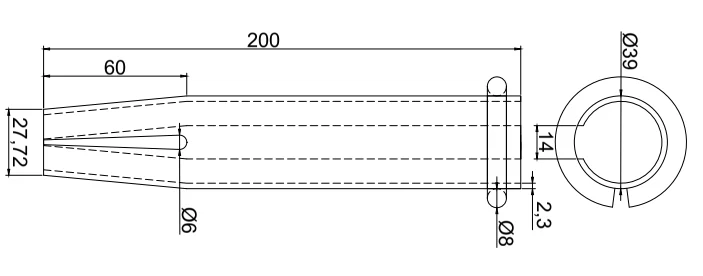

1/Split set making machine:Split set outer diameter: 39mm ( we can make as your personal requirement)

Material thickness: 2.5-3.0mm

Here below product details drawing and machine photos for you reference:

Here our machine specifications for you check:

Decoiler - feeding - roll forming - cutting at the same time make the notch - receiving table

|

Item name |

Parameters |

|

Decoiler |

3t loading capacity manual decoiler |

|

Feeding rollers |

2 rollers |

|

Guiding rollers |

2 rollers |

|

Forming machine rollers |

7 rollers |

|

Transmission |

Gear box |

|

Drive motor power |

15kw |

|

Voltage |

415v 50hz 3phase or as customer requirement |

|

Machine structure |

Memorial arch roller fixer with middle plate weld base |

|

Forming speed |

0-15m per min |

|

Supported material |

2.4-3.2mm |

|

Shaft diameter |

70mm |

|

Roller material |

Cr12 with quench treatment |

|

Hydraulic station power |

5.5kw (supply power for notching and shearing) |

|

Main forming machine size |

About 6000 mm×1400 mm×1500 mm |

|

PLC computer control |

Delta brand (famous) from TAIWAN |

|

Shearing type |

Hydraulic power stop shearing and at the same time make the notch |

|

Receiving table |

2.5m length per piece |

Here below are the other machines we can make for you:

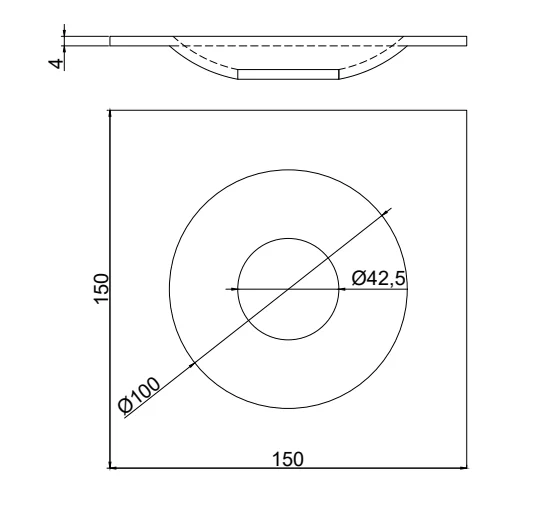

2/Split set plate press machine:This product use the HYDRAULIC OIL machine to process.

The holes punching and shape pressing will at the same time.

Customer requirements:

Material thickness: 4.0 mm

Here below holes and other sizes details drawing and machine photo for you reference:

This machine used for the necking of the finished split D39

Hydraulic motor power: 3kw

Mould material: GCr12

We have other machines also if you need:

4/Split set ring making machine

If you have demand of those above machines, please let us know and we can prepare the detail machine offer for you, thanks.

اللغة العربية

اللغة العربية